Cleaning methods are as varied as the types of surfaces, substrates, and particles that exist. Not only is it important to consider all of these factors, it is necessary to think about how particles not only adhere to substrates, but also interact with and attach to each other. This is why there is no one-size-fits-all type of cleaning approach that works for every application.

The Mechanics of Cleaning

The mechanics of cleaning involve the removal of either soluble or insoluble contaminants, or a combination of both. Ultrasonic cleaning is the preferred method for the removal of soluble contaminants and particles that are less than approximately 6mm in size.

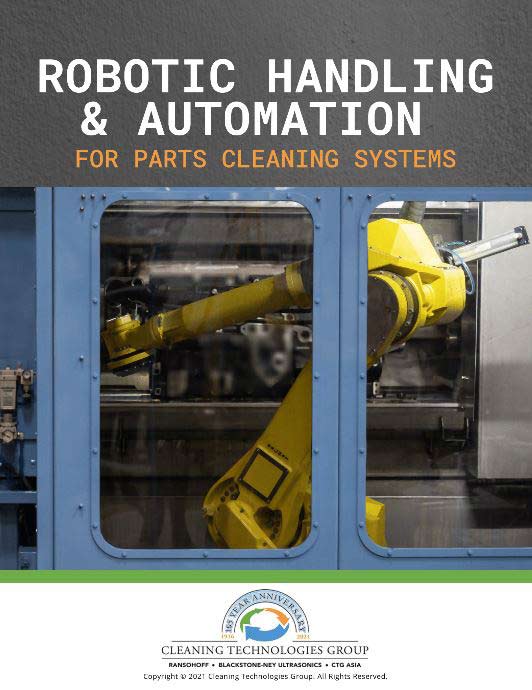

In today’s manufacturing world, a wide range of businesses are increasing efficiency and improving production with robotic parts washing and other customized automated washing solutions. Automated washing systems offer the added benefit of improving product quality and consistency, while freeing valuable human labor resources for other tasks.

While highly beneficial, the introduction of robotics and automation may initially seem overwhelming to manufacturers who lack experience with this technology. Cleaning Technologies Group (CTG) has significant experience and expertise in the development of parts washing systems which include integrated robotic handling and customized automation. We have developed a new first-step guide designed to introduce businesses to the benefits of implementing automated and robotic parts washing systems. Topics include:

- A New Dimension of Capability and Cost Savings

- Programmable Controls for Robotic Parts Handling and Parts Cleaning

- Robot Tended Cells and Modular Design Systems

- Robotic Parts Cleaning In Action

Cleaning Technologies Group will introduce a host of advanced cleaning solutions at Eastec 2021 in West Springfield, Massachusetts October 19 - 21, 2021. Exhibiting in Booth #3127, CTG will showcase a variety of new products, technologies, and services.

EASTEC 2021

EASTEC 2021, the largest Northeast manufacturing trade show, promotes the historical importance of manufacturing while showcasing its future in leading-edge industries such as aerospace, medical devices, automotive, industrial equipment and defense.

New technologies that CTG will be exhibiting at the show include:

JAMESTOWN, NY – The CTG family of companies is proud to recognize three Blackstone-NEY Ultrasonics employees who stepped into a perilous situation to help save a life.

Merle Delcamp, Dean Bennett, and Patti Carlson, employees of Blackstone-NEY Ultrasonics, each played an important role in the rescue of a local man who was in extreme danger.

When Merle Delcamp and Dean Bennett arrived for work at 6:30 am on Monday, July 19th, they noticed area resident, Mike Campbell, attempting to rescue a man in distress. The victim was an older man who appeared to have fallen into the Chadakoin River and was clinging to a tree.

The river’s rushing current was making the situation especially dangerous, as the three men worked to save the weakened man from the water. A steep cement bank was also impeding the progress of the rescue, making it too difficult for the men to pull the victim to safety.

Blackstone-NEY Ultrasonics proudly introduces the Torrent M Series automated ultrasonic aqueous cleaning systems for high precision Medical and Pharmaceutical cleaning applications. The Torrent is a single chamber, front loading rotary basket style machine that features 640 watts of Blackstone-NEY single or multi-frequency Ultrasonics for vacuum and non-vacuum immersion wash or rinse, basket rotation with user selected speed, direction and short cyclic modes, compressed air blow off, spray rinsing and hot air dry or vacuum dry with hot air assist.

The Torrent M Series machines are self-contained, skid mounted machines designed for both single pass or multiple pass chemistries utilizing onboard reservoirs while reducing water consumption through a broad range of user defined machine operation parameters.

Blackstone-NEY helps automotive component manufacturers improve cleaning efficiency with a wide range of cleaning solutions that meet the challenges of automotive component cleaning. From remanufacturing to precision electronics and fluid system components, Blackstone serves a diverse range of automotive industries. We regularly design and manufacture system solutions to help our customers meet ISO 16232 and VDA 19.1 driven technical cleanliness specifications.

Specialized Cleaning for Tech Components

Blackstone Aquarius and Agisonic are two systems that offer an ideal cleaning solution for EV sensors and similar types of components.

Aquarius ultrasonic cleaning provides complete cleaning in one step. Combining ultrasonic cleaning with rinsing, drying, and other processing steps in a unitized cleaning console promotes process integrity. The versatile Aquarius can be customized with an automated, robotic transfer, environmental enclosure, and DI water system to increase cleanliness levels and provide process consistency. Labor required for parts cleaning is also significantly reduced.

Cleaning Technologies Group is committed to quality and maintaining a program of continuous improvement. This commitment includes maintaining ISO 9001:2015 certification. We are proud to announce that we have met the rigorous requirements and have once again qualified for ISO 9001-2015 certification across all of our factories.

Our team is dedicated to improving upon our manufacturing process across all of our facilities on an ongoing basis so we may continue to produce high quality parts cleaning equipment, and offer service and support

Ransohoff, a division of Cleaning Technologies Group LLC, is proud to announce its partnership with Stoelting Cleaning Equipment, a division of The Vollrath Company, LLC. Ransohoff will expand its current operations to include the manufacturing of the Stoelting industrial parts washer lines for their global customers.

Founded in 1905, Stoelting Cleaning Equipment has developed a solid reputation as a top cleaning equipment manufacturer. Driven by a shift in Stoelting’s strategy, Ransohoff will now provide new and replacement equipment for its existing parts washer customer base. Ransohoff can also provide machines for any new applications.

Ransohoff is well suited to meet the challenges of cleaning automotive components. Many manufacturers of automotive parts and assemblies have improved cleaning efficiency with dependable Ransohoff cleaning solutions. Whether the application demands heavy soil removal or intricate cleaning, our innovative cleaning systems enhance productivity and efficiency, while delivering superb cleaning. We also develop system solutions to help our customers meet ISO 16232 and VDA 19.1 driven technical cleanliness specifications.

LeanVeyor Parts Cleaning Systems

Ransohoff LeanVeyor systems are widely used in automotive applications, particularly for cleaning automotive gears.

For example, for the cleaning of ring and pinion gears, a manufacturer needed a solution for cleaning grinding swarf and oil at a rate of .55 milligrams per gear set for an axle with 70oz of fluid fill. The cleaning system needed to keep pace with a production rate of 72 sets per hour and incorporate a drying system to get the components completely dry. The company also needed a system with as small a footprint as possible.

CTG is pleased to announce that our Ransohoff division has introduced its Cell-U-Clean Cell Jet spray cabinet. This new small footprint platform provides an energy efficient, reliable solution for your high-volume cleaning needs, along with an innovated design for smaller part cleaning applications.

The Cell-Jet, a member of our Cell-U-Clean line of parts washers, is an excellent cabinet washer for point of use, batch cleaning where very little floor space is available. This spray washer was designed as a lower cost, industrial quality wash station utilizing spray impingement and compressed air to clean and dry your parts. The option for robot loading and unloading makes it a great choice for cell applications where cleaning specification are critical to the application. A heated blowoff option is available when a dry part is required.

English

English Spanish

Spanish Chinese

Chinese Canada

Canada Mexico

Mexico United Kingdom

United Kingdom