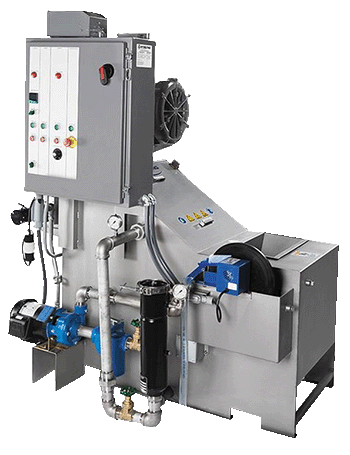

Ultrasonic cleaning is a proven method for the safe and effective removal of contaminants from optical components and assemblies. The compounds are used to polish mating surfaces to a perfectly smooth flat surface. In these applications it is absolutely critical that complete cleaning is accomplished while also avoiding scratching or otherwise compromising the product.

The sensitive components used in laser and optic applications must be precision cleaned to provide optimal performance. When contaminants such as smoke or resin accumulate on parts, available power to the equipment is reduced, and may result in damage. Anything less than entirely clean optics can also significantly reduce engraving and cutting quality.

Blackstone-NEY Ultrasonics offers a host of cleaning technologies that meet the unique requirements involved with the cleaning of optics, flat panel, and laser components. Our team has developed customized solutions for glass and quartz etching, rinsing, LCD display grade glass, prisms, polycarbonate and ophthalmic lens, laser and fiber optics, aluminum device housings, and more.

Read more

English

English Spanish

Spanish Chinese

Chinese Canada

Canada Mexico

Mexico United Kingdom

United Kingdom

Cleaning Technologies Group, LLC (CTG) announces the relocation and expansion of its Blackstone-NEY Ultrasonics division to Cincinnati, Ohio. This strategic move is designed to enhance operations and accelerate growth for the division, which is a global leader in both industrial...

Cleaning Technologies Group, LLC (CTG) announces the relocation and expansion of its Blackstone-NEY Ultrasonics division to Cincinnati, Ohio. This strategic move is designed to enhance operations and accelerate growth for the division, which is a global leader in both industrial...